CBS.1R

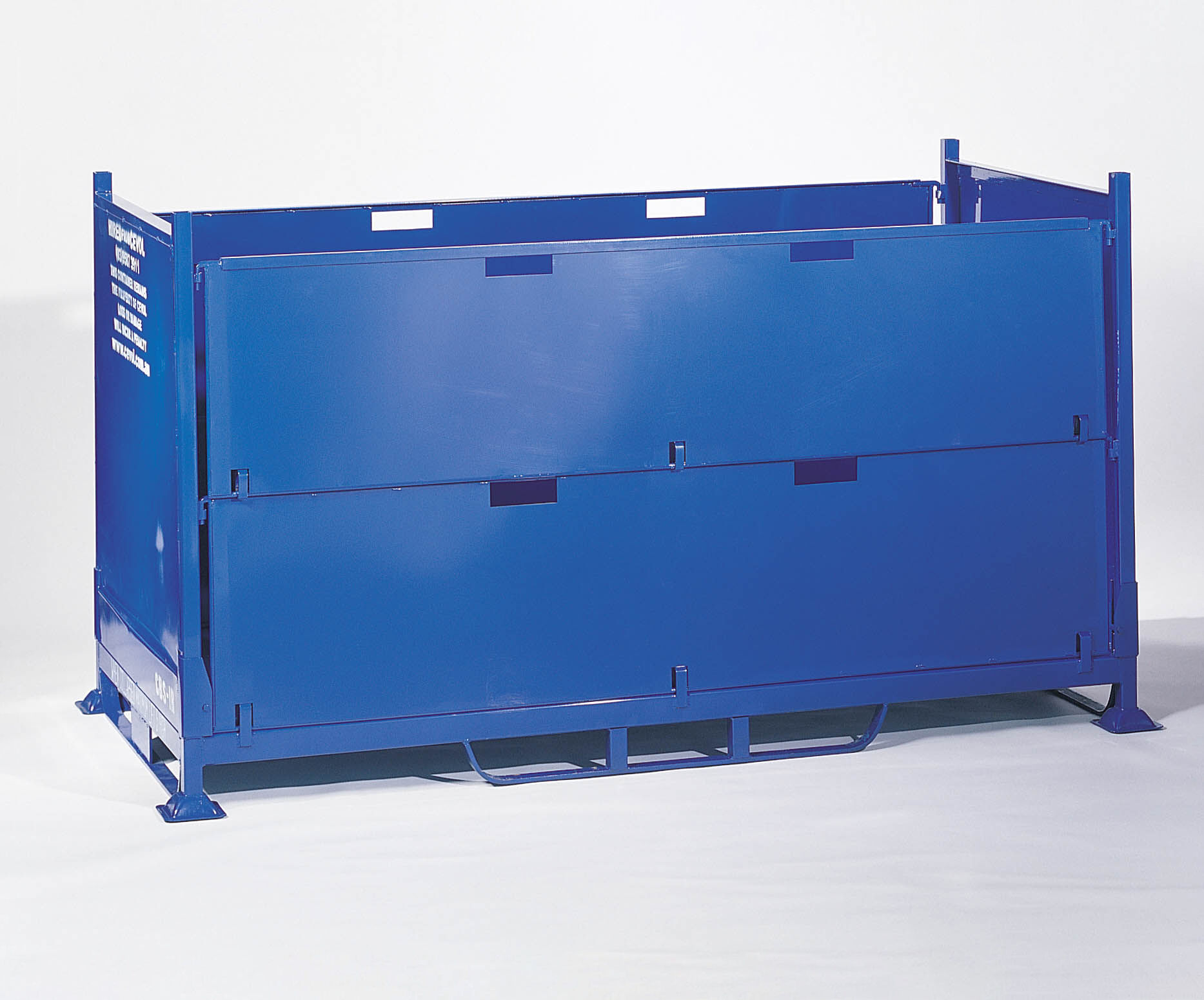

Folding Bulk Sheet Stillage with half drop front & back gates

Folding pallet offering bulk storage and visual product identification. Four folded, equals one built up. Sides are not removable, therefore cannot be lost. Can also be made with a lockable security lid pallets are interstackable.

Specifications

Design Specifications

Stillage Assembly

- Ends: Pull each of the two folding sides to their fully open positions. If the two ends are not fully open, then erecting the gates becomes difficult.

- Gates: Hold onto the top of one gate and lift all the way to its upward limit. Locate bottom half gate hooks into bottom catches on each post. Then locate the top half gate hooks into the top catches on each post.

- Check Assembly: When assembly is complete, double check all posts to make sure all gate hooks are located fully. Visually check entire pallet to make sure it is in safe usable condition.

Stillage Safety Assessment

- Pallet feet are not bent or broken

- Gates fully locate into their catches

- Rack runners are in safe usable condition

- Stillage ends are properly attached to the stillage base

- Nuts & bolts are all tigh

- Posts are not damaged and that stillage can be stacked or stacked onto

General Loading & Trucking of Stillage

- Always evenly distribute the loading of product into the stillage as best as possible

- When stacking stillages, make sure the stillage has interlocked properly before removing the forklift

- Avoid having heavy loads on top of the stack

- When erect stillages must be loaded long ways across the truck. Ropes or straps must pass over the top of the stillage at each end. Stillage gates are not designed to be used as the tie down point

Stillage Damage & Repairs

- Damaged stillages should be assessed and if deemed to be unsafe, removed from circulation

- Any time a stillage is removed from circulation, it should be reported to the relevant supervisor

- Damaged or unsafe stillages are to be returned to Cevol Industries for proper assessment or repair

Operators Guide

Operators are not to exceed any of the design specifications listed above.

Each stillage hired out by Cevol Industries is in a safe usable condition, stenciled with the maximum capacity and stacking height.

Operators are to report any damaged stillage to their supervisor for assessment or return to Cevol Industries.

OFFICES

Melbourne Victoria (HQ)

2-4 Crawford Street,

Braeside,Victoria - 3195 Australia

P: 1800 643 911

E: salesvic@cevol.com.au

Contact: Tara Rea - 0418 153 118

Sydney NSW

56-58 Power St,

St Marys, NSW - 2760 Australia.

P: 1800 643 911

E: salesnsw@cevol.com.au

Contact: Jodie Brown - 0407 839 775

Brisbane QLD

37-43 MacBarry Place,

Rocklea, Qld - 4106 Australia.

P: 1800 643 911

E: salesqld@cevol.com.au

Contact: Emily Dixon - 0448 448 099

Perth WA

3 Hanwell Way,

Bassendean, WA - 6054, Australia.

P: 1800 643 911

E: saleswa@cevol.com.au

Contact: Chris Didlock - 0400 005 113